THE WAY TO BATCH SIZE 1

The market for intelligent building automation is currently experiencing high dynamics. Busch-Jaeger is also facing up to this challenge. In response to increasing customer requirements, the manufacturer of building system technology realigned its supply chain. The anonymous warehouse producer thus became a manufacturer of individual products.

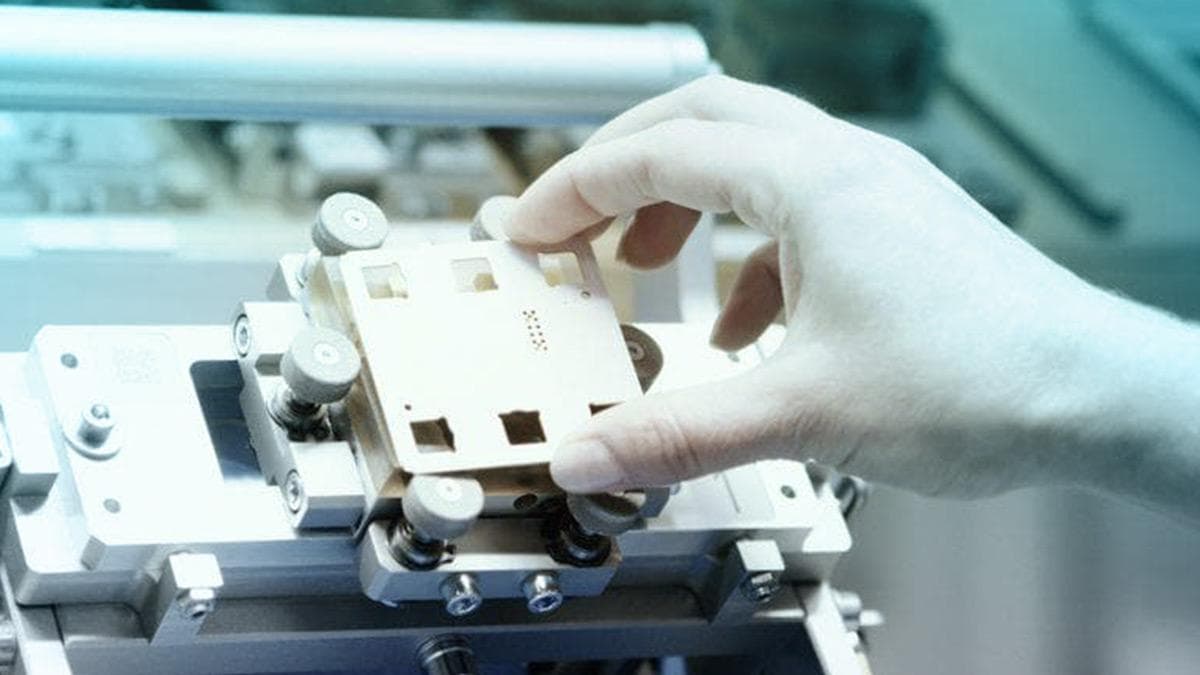

The market for smart home products is growing rapidly and so is the demand for customized products. The changed consumer behavior in the B2B sector leads to increased demands in terms of delivery time, transparency, user-friendliness and flexibility. In order to react to these trends, Busch-Jaeger has introduced a completely new process at its location in Lüdenscheid for the production of individualized Busch-tacteo KNX glass sensors as part of its series production.