Project focus

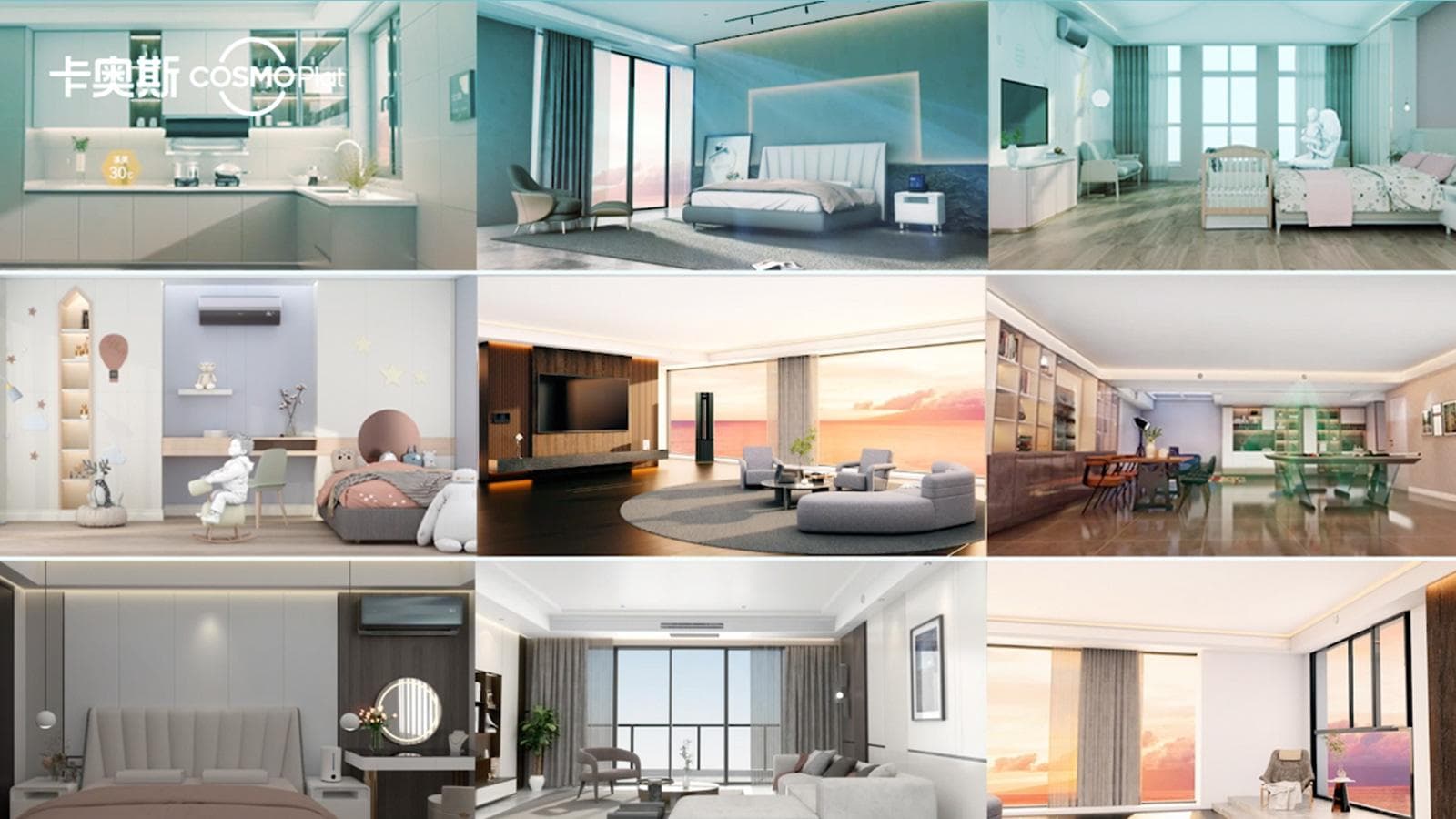

The Chinese industrial group Haier is one of the global market leaders in the field of large household appliances. The company manufactures smart, connected products such as kitchen appliances (Laiyang plant) or air conditioners (Jiaozhou plant) and offers its suppliers and customers corresponding, forward-looking services.

ROI-EFESO honored both Haier plant locations with the INDUSTRIE 4.0 Award in the “Smart Service” category. The Industry 4.0 solutions already successfully implemented there focus both on continuous improvement of production and logistics and on further development of the products as well as the related services offered.