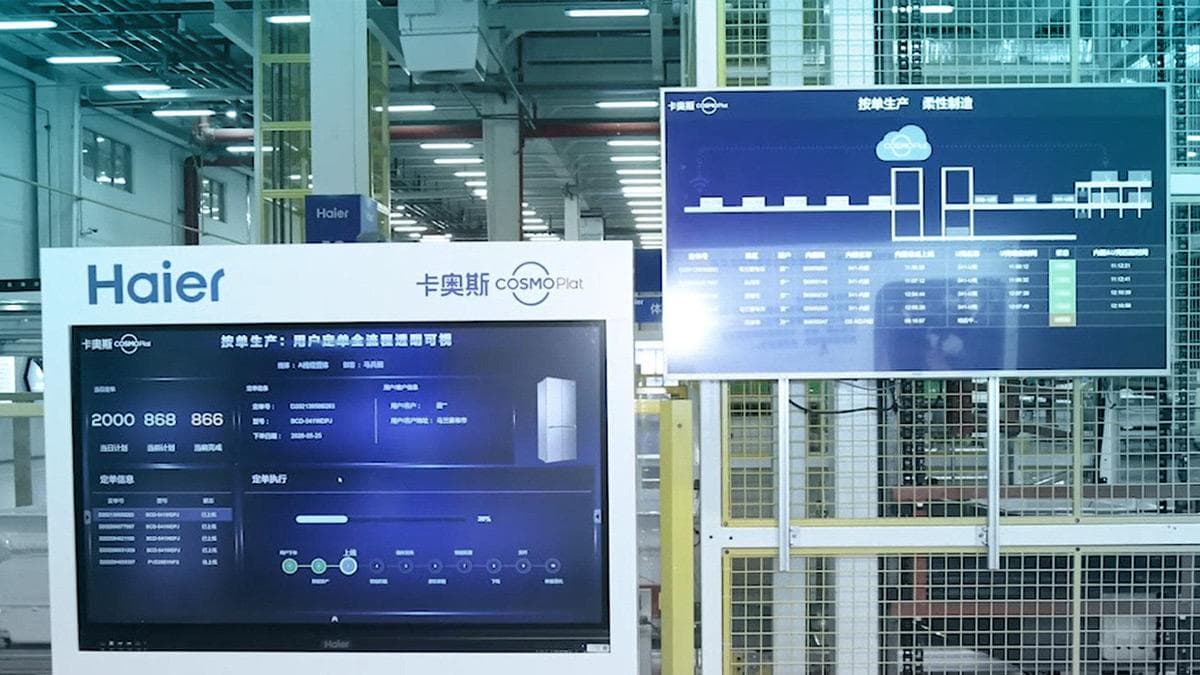

Mass Customization Model and Interconnected Factory

At Haier Sino-German Intelligent Park in Qingdao, China, elextronics group Haier is using an exceptionally innovative IIoT solution. In contrast to the use of IIoT solutions in a single factory, the entire industrial park uses a uniform, intelligent production system.

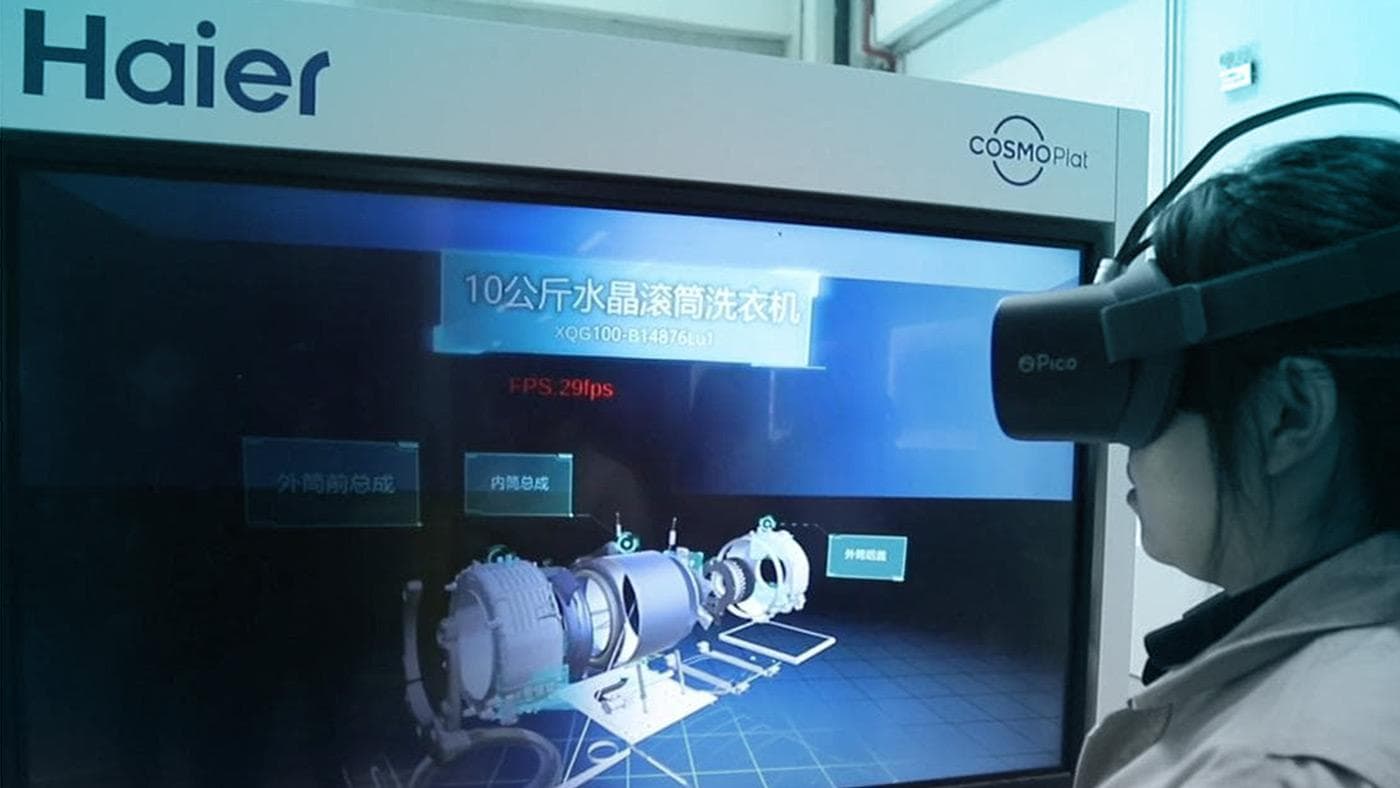

Its core is a “smart” manufacturing system for mass production according to individidual customer requirements. An R&D production system also ensures an optimal exchange of information. Haier uses this system to network four factories that manufacture alternating current systems, refrigerators, washing machines and water heaters.

At the heart of the solution is the online platform COSMOPlat, with which the company interacts directly with its customers and thus quickly identifies their needs. This provides flexibility for subsequent order changes, shortens delivery cycles and avoids high stock levels. Above all, however, customer experience is a valuable asset in the further development of the products.