Project focus

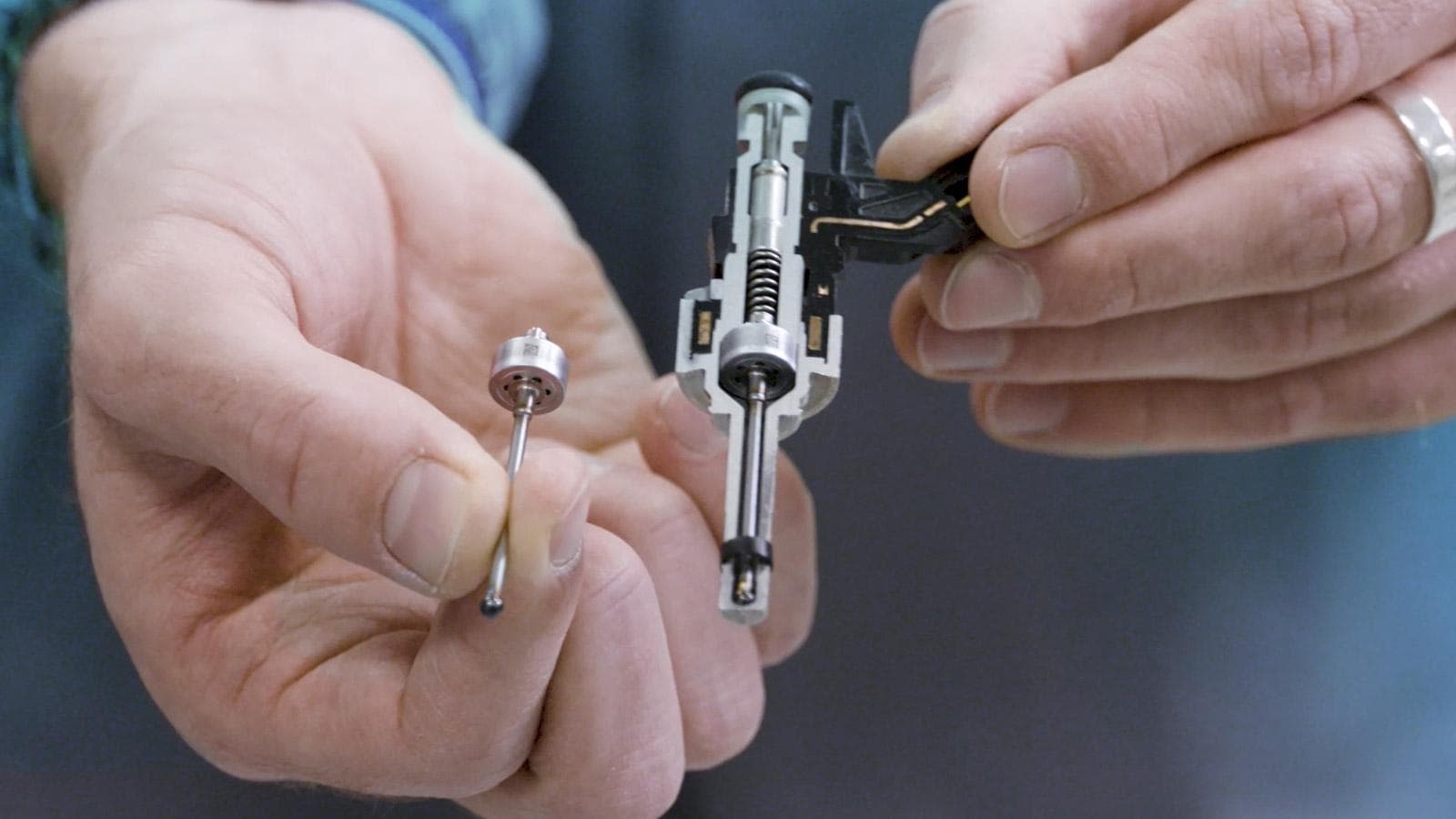

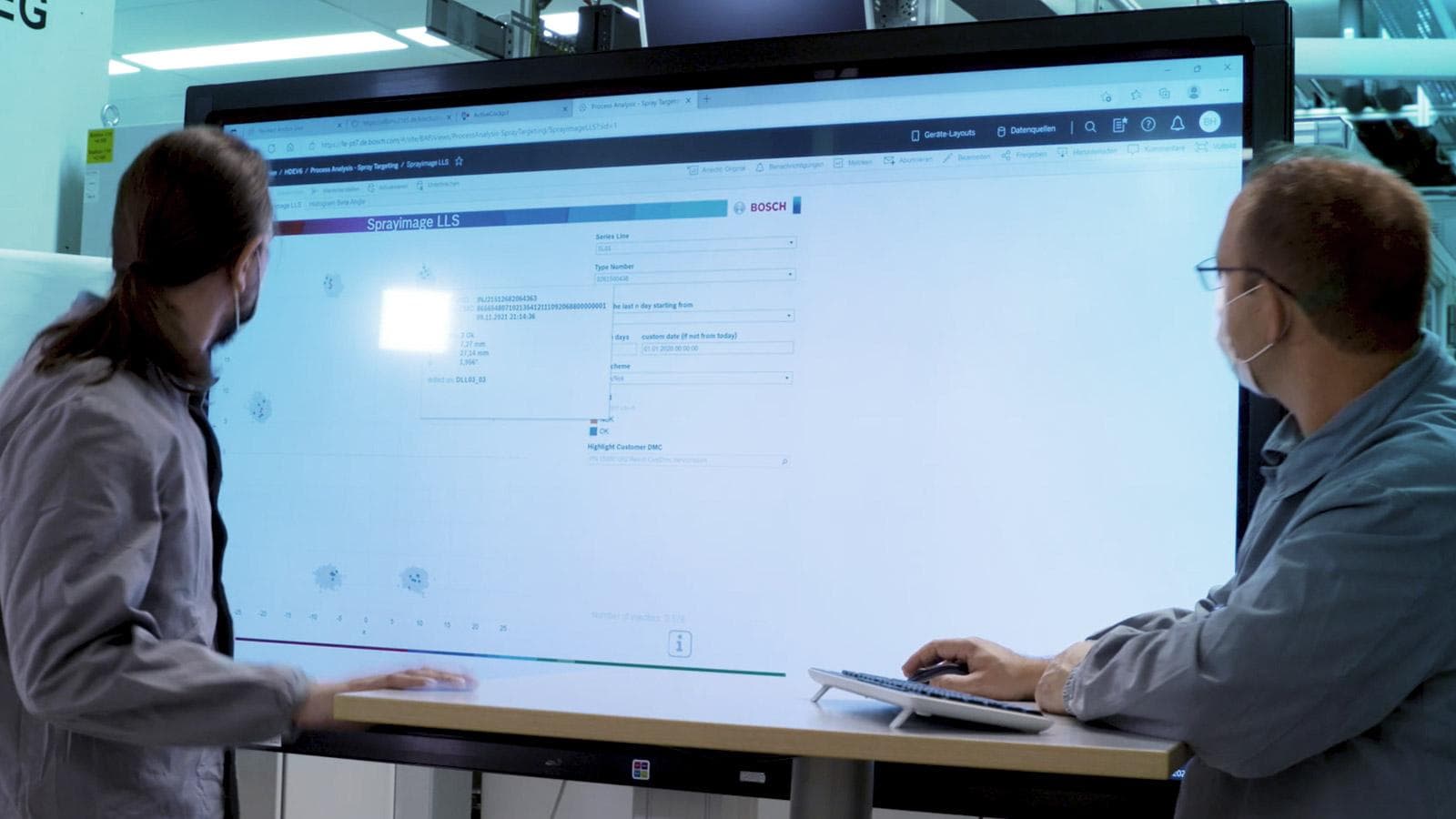

Bosch Bamberg is not only the largest manufacturing location in Germany within the Bosch Group, but also the lead plant for diesel technology in the global production network. The company is investing in both the expansion of fuel cell production and in the further development of internal-combustion engine components. As part of the Industry 4.0 project, the lines for the production of fuel injectors for gasoline, gas and diesel engines are to be fully automated and digitized at four locations.