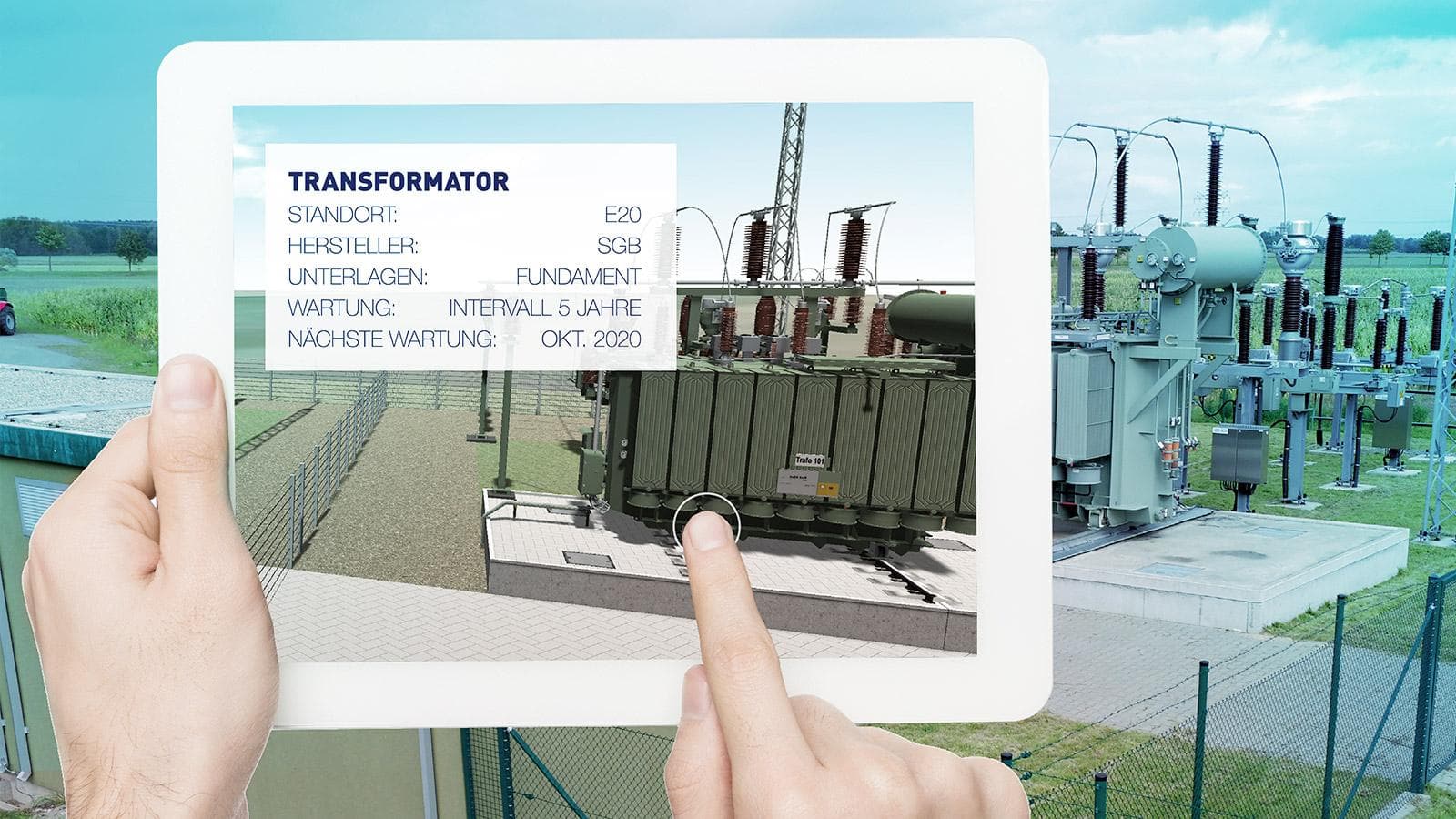

Project focus

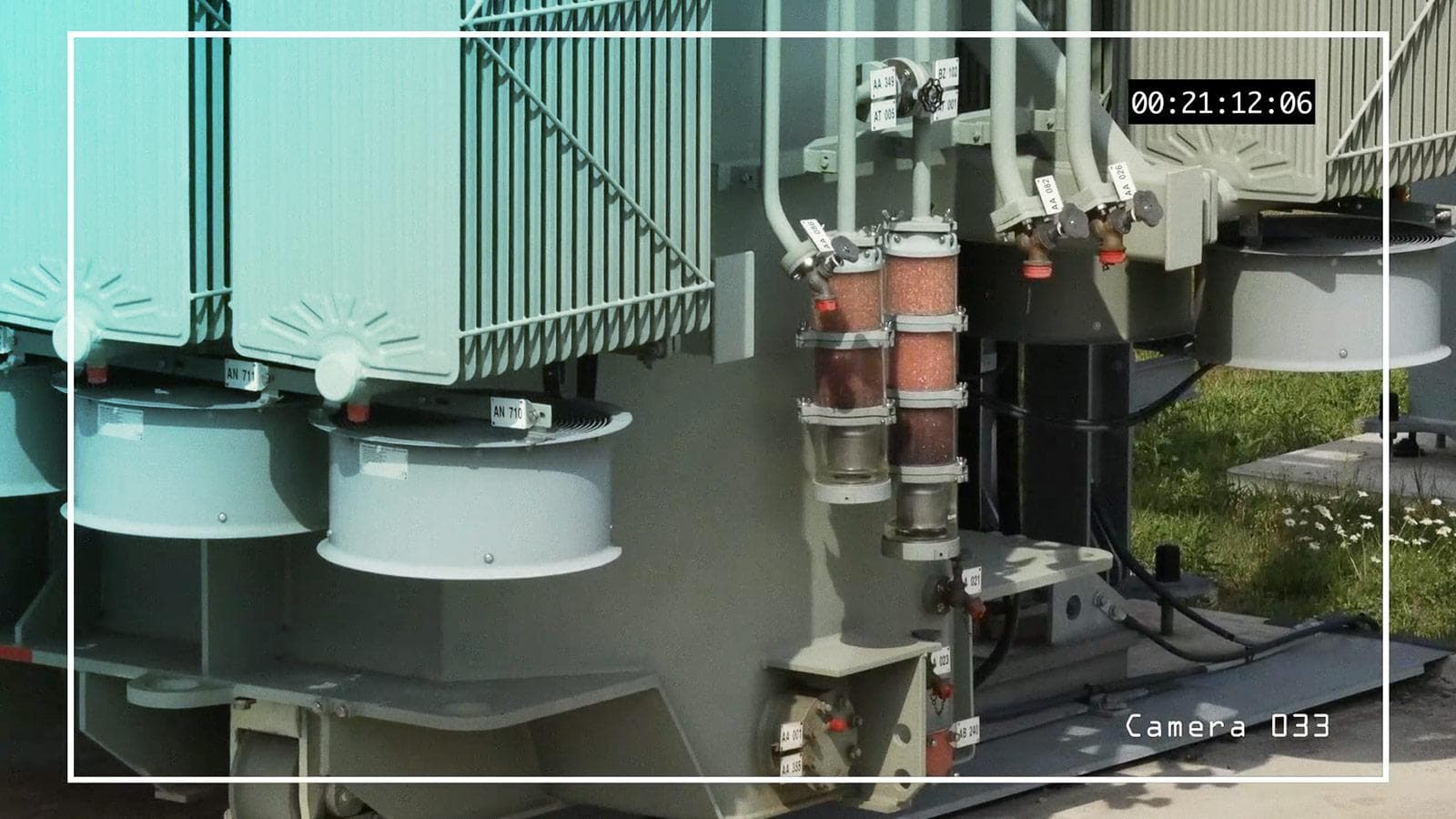

SPIE SAG GmbH is a service provider in the area of high-voltage power distribution, such as the planning, construction, commissioning and maintenance of power plants and transformer stations. As these are central elements in the critical infrastructure of the energy industry, owners are legally obliged to ensure the continuous operation of these facilities.